Major types of surface disinfectants and their action mechanism

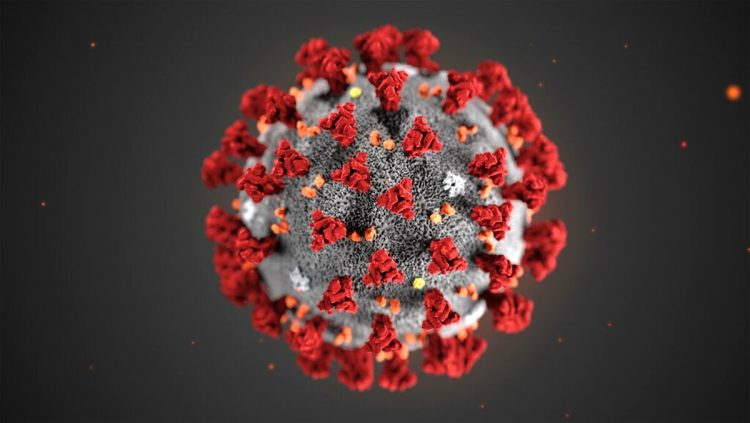

The tornado of COVID-19 pandemic has changed everyone’s life upside down. It has brought major changes in our lifestyle. Now, people are more cautious about personal hygiene, cleaning of their surroundings which they took casually earlier. Now, disinfectants and sanitizers are necessary essentials of individual’s lives. Disinfection or sanitization of the surfaces we get in touch with on regular basis is much more important than sanitizing or cleaning of ourselves. Surface disinfectants play a vital role to effectively serve the purpose disinfection by eliminating the presence of microbial agents exists almost everywhere in the surrounding. There are varieties of surface disinfectants available having different antimicrobial properties based on their action mechanism, and particularly effective on distinct microbes.

Basis on the mode of action mechanism, the disinfectants are classified in to two categories:

Oxidizing Disinfectants: These oxidizing agents attack the cellular material by oxidizing the cell membrane of the microorganism, which results in loss of structure and leads to cell-lysis and death. Peracetic Acid, Hydrogen Peroxide and Sodium Hypochlorite are examples of oxidizing disinfectants.

Non-oxidizing disinfectants: These disinfecting agents penetrate the cell wall of the microorganisms and disturb the phospho-lipid molecules which make up the cell membrane; thereby blocking the metabolic pathways needed for the organism to survive and /or cause it to leak vital chemicals. Quaternary ammonium compounds (quats), such as benzalkonium chloride and alcohols are examples of non-oxidizing disinfectants.

Different types of disinfectants and their mode of action

Alcohols: Usually, ethanol and propanol are two water-soluble alcohols which are used for the disinfection purpose. Absolute alcohols are not very effective against microbes; however their efficiency increases when mixed with water. The maximum bactericidal concentration for ethanol and isopropanol is in the range of 60% to 90% by volume. On diluting below 50% concentration, their cidal activity sharply drops. These are highly effective against wide spectrum of bacteria including mycobacteria and vegetative bacteria, viruses and fungi, but they do not eliminate bacterial spores. Ethanol in water at a concentration range of 60-80%, acts a potential virucidal agent in destroying lipophilic viruses such as vaccinia, herpes and influenza virus and hydrophilic viruses, including rhinovirus, adenovirus, enterovirus, and rotaviruses. Isopropanol is more effective on lipid viruses.

The most feasible modes of action of alcohol are disruption of cellular membranes, solubilisation of lipids and denaturation of proteins by attacking directly on S-H functional groups present in cellular structure of microbes.

They are majorly used in hand disinfection; [1]to disinfect oral and rectal thermometers, hospital pagers, scissors, and stethoscopes; [2]wipe down interior of Biological Safety Cabinets and bottles, and other equipments to be put into Biological Safety Cabinets etc.

Quaternary ammonium compounds: Alkyl dimethyl benzyl ammonium chloride, alkyl didecyl dimethyl ammonium chloride, and dialkyl dimethyl ammonium chloride are some mostly commonly used quaternary ammonium compounds. They are effective against gram positive and gram negative bacteria, fungi, lipophilc (enveloped) viruses. But, they possess poor microbicidal activity against bacteria spores, mycobacterium tuberculosis and hydrophilic (non-enveloped) viruses.

The bactericidal action of the quats has been associated to the inactivation of energy-producing enzymes, denaturation of essential cell proteins, and disruption of the cell membrane. The quaternary ammonium compounds based disinfectants are generally used for sanitation of noncritical surfaces, such as floors, furniture, and walls. However, EPA registered quaternaries such as benzalkonium chlorides (BACs) for sanitizing medical equipments. BACs are the most frequently used active ingredients in disinfectants for varied applications including residential (walls, floors, toilets, water storage tanks, swimming pools, decorative ponds and fountains etc.), industrial (hospitals, food industry and consumer products), agricultural tools and vehicles and clinical settings ( medical equipments).

Peroxides:

Peracetic: Peracetic, or peroxyacetic, acid is generally known for rapid action against all kinds of bacteria, fungi and yeasts. These are majorly used in the beverage and brewing industries since they are low foaming, can be used in small concentrations at low temperatures. The special advantages of peracetic based disinfectants are that enhances removal of organic material, do not break down into decomposition harmful products (such as, acetic acid, water, oxygen, hydrogen peroxide) and leaves no residue.

The action mechanism of peracetic acid is like oxidizing agents through destruction of cellular materials. This is done by denaturing the proteins, disrupting the cell wall permeability and oxidizing sulfhydryl and sulphur bonds in proteins, enzymes, and other metabolites.

The major disadvantage of peracetic based disinfectants is their corrosive nature. They can potentially corrode the surface of metals and alloys such as plain steel, galvanized iron, copper, brass and bronze. They are also unstable, particularly on dilution, since the strength of their active materials reduces within short period of time due to hydrolysis.

Hydrogen peroxide: It is an effective germicidal agent against a wide range of microbes such as bacteria, viruses, yeasts, fungi and spores. A 0.5% hydrogen peroxide is effective to kill various bacteria and viruses in 1 minute and mycobacteria and fungi in 5 minutes. Alfa et al. also demonstrated that a 0.5% hydrogen peroxide antimicrobial is highly efficient at disinfecting medical devices.

Hydrogen peroxide attacks by producing destructive hydroxyl free radicals that can attack membrane lipids of microbial agents, DNA, and other essential cell components.

Generally, 3% to 10% hydrogen peroxide solution is commercially available for household use. The typical 3% hydrogen peroxide concentration found in stores can be used as a disinfectant, it is recommended to dilute it to a 0.5% concentration, which still has some effectiveness, using a mixture of 2.5 parts water and 0.5 parts 3% hydrogen peroxide. [1]3% to 6% of hydrogen peroxide solution has been used for disinfecting soft contact lenses for about 2–3 hrs. It is also used in hospitals for disinfecting medical equipments such as ventilators, endoscopes, tonometer and fabrics in patients’ room.

Hydrogen peroxide and peracetic acid: The combination of hydrogen peroxide and peracetic acid can effectively inactivate all the microbes except bacterial spores within a time span of 20 minutes. The action mechanism of this combination is similar as demonstrated above as peracetic and both hydrogen oxide are strong oxidizing agents. These hydrogen peroxide and peracetic acid based disinfectants are majorly used for disinfecting medical devices.

Halogen compounds

Sodium Hypochlorites: The sodium hypochlorite is the most widely used chlorine disinfectant. It is very effective to destroy and prevent the growth of all types of microorganisms including spores. Sodium hypochlorite is also used as household bleach in the concentration range of 5.25 to 6.15%.

The mechanism of action causes biosynthetic alterations in cellular metabolism and phospholipid destruction, formation of chloramines that interfere in cellular metabolism, oxidative action with irreversible enzymatic inactivation in bacteria, and lipid and fatty acid degradation. The effectiveness of sodium hypochlorite in the cleaning and disinfection processes depends on the concentration of available chlorine and the pH of the solution. Hypochlorous acid (HOCl) is a weak acid and dissociates to the hypochlorite ion (-OCl) and proton (H+) depending on the solution pH. Generally, it is believed that HOCl is the active species in the germicidal action, whereas the concentration of -OCl is a key factor determining the cleaning efficiency.

Sodium hypochlorite (NaOCl) is a versatile disinfectant used in the [8]food industry, health care facilities include as an irrigating agent in endodontic treatment and as a disinfectant for manikins, laundry, dental appliances, hydrotherapy tanks, regulated medical waste before disposal, and the water distribution system in hemodialysis centers and hemodialysis machines water irrigating system, for spot-disinfection of countertops, floors, doors and building walls.

Iodophors: It is a combination of iodine and a solubilizing agent or carrier, thereby the resulting complex provides a sustained-release reservoir of iodine and releases small amounts of free iodine in aqueous solution. Iodophors are expensive but incredibly effective disinfectants having the ability to kill a wide range of organisms such as bacteria, mycobacteria and viruses at low temperatures, short contact time. But, it requires long contact time to kill bacterial spores and fungi.

The action mechanism of iodophors has been attributed as iodine penetrates the cellular wall of microorganisms rapidly, thereby disrupting the protein and nucleic acid structure of microorganisms.

The applications of iodophors include disinfection of blood culture bottles and medical equipment, including hydrotherapy tanks, thermometers, and endoscopes; and noncritical surfaces such as farm gate foot baths and drive-over disinfectant blankets etc.

Phenolics: The phenolics are bactericidal, virucidal, and fungicidal and tuberculocidal in nature and effective against [2]enveloped viruses, rickettsiae, fungi and vegetative bacteria. Ortho-phenylphenol (OPP), Chloroxylenol, Para-tert-amylphenol and Ortho-benzyl-para-chlorophenol are some examples of active ingredients of phenol based disinfectants.

Phenols have different mode of actions at different concentration levels. Generally, Low concentrations of phenol and higher molecular-weight phenol derivatives cause bacterial death by inactivation of essential enzyme systems and leakage of essential metabolites from the cell wall. But, it acts as a protoplasmic poison, penetrating and disrupting the cellular wall and precipitating the cell proteins, at high concentrations.

Various phenolic germicides are EPA-registered disinfectants for disinfection purpose of environmental surfaces (e.g., bedside tables, bedrails, and laboratory surfaces) and noncritical medical devices. The major disadvantage of phenolic compounds based disinfectants is that they are toxic and corrosive substances in nature.

Aldehydes: Formaldehyde and glutaraldehyde are two commonly known active ingredients in aldehyde based disinfectants and sterilants. They have broad spectrum of activity against bacteria, fungi, and viruses.

The general action mechanism of aldehydes is alkylating the cellular proteins of microorganism. For instance, Formaldehyde inactivates microorganisms by alkylating the amino and sulfhydral groups of proteins and ring nitrogen atoms of purine bases. Glutaraldehyde alters the RNA, DNA and protein synthesis through alkylation of sulfhydryl, hydroxyl, carboxyl, and amino groups of microorganisms.

Aldehyde based disinfectants are majorly used for sterilising medical devices such as catheters. Glutaraldehyde based solutions used as high-level disinfectant for medical equipment such as endoscopes, dialyzers, transducers, thermometers, spirometry tubing, anesthesia and respiratory therapy equipment, hemodialysis proportioning and dialysate delivery systems etc.

The major advantages of glutaraldehyde-based solutions includes excellent biocidal properties; activity in the presence of organic matter and noncorrosive action to rubber, or plastic equipment.

The disadvantages of aldehydes are highly toxic nature and a long contact time is required to kill microbial agents. Formaldehyde releases irritating fumes and pungent odor even at low level (< 1ppm).

The kinds of disinfectants discussed in this article are the major surface disinfectants known.

The effectiveness of a disinfectant depends on two vital factors that are contact time and concentration of active ingredients in the disinfection solution. However, few disinfectants are effective within minutes whereas many take at least 15-20 minutes of contact time. Less contact time and contact time could result in an ineffective reduction of microbes on the sanitized or disinfected surface.

The increasing awareness about the hygiene and cleanliness among individuals is predominantly drives the global surface disinfectant market in last few years. According to reports, the global surface disinfectant market is expected to grow at a Compound Annual Growth Rate (CAGR) of 11.70% during the period 2017-2021. Surface disinfectants manufacturers are endorsing new technologies to produce innovative product and enhance the efficiency of the developed products, in order to differentiate them from the existing ones in the market.

This article is based on the data collected from on-line articles and publications. For on-line references please contact the author Mr. Neelakamal Mohapatra Article source: http://articlebiz.com

No Comment